Our Story

How it all began...

We are family owned and operated business that started on its journey in 2002. Based in Redruth, in the heart or Cornwall.

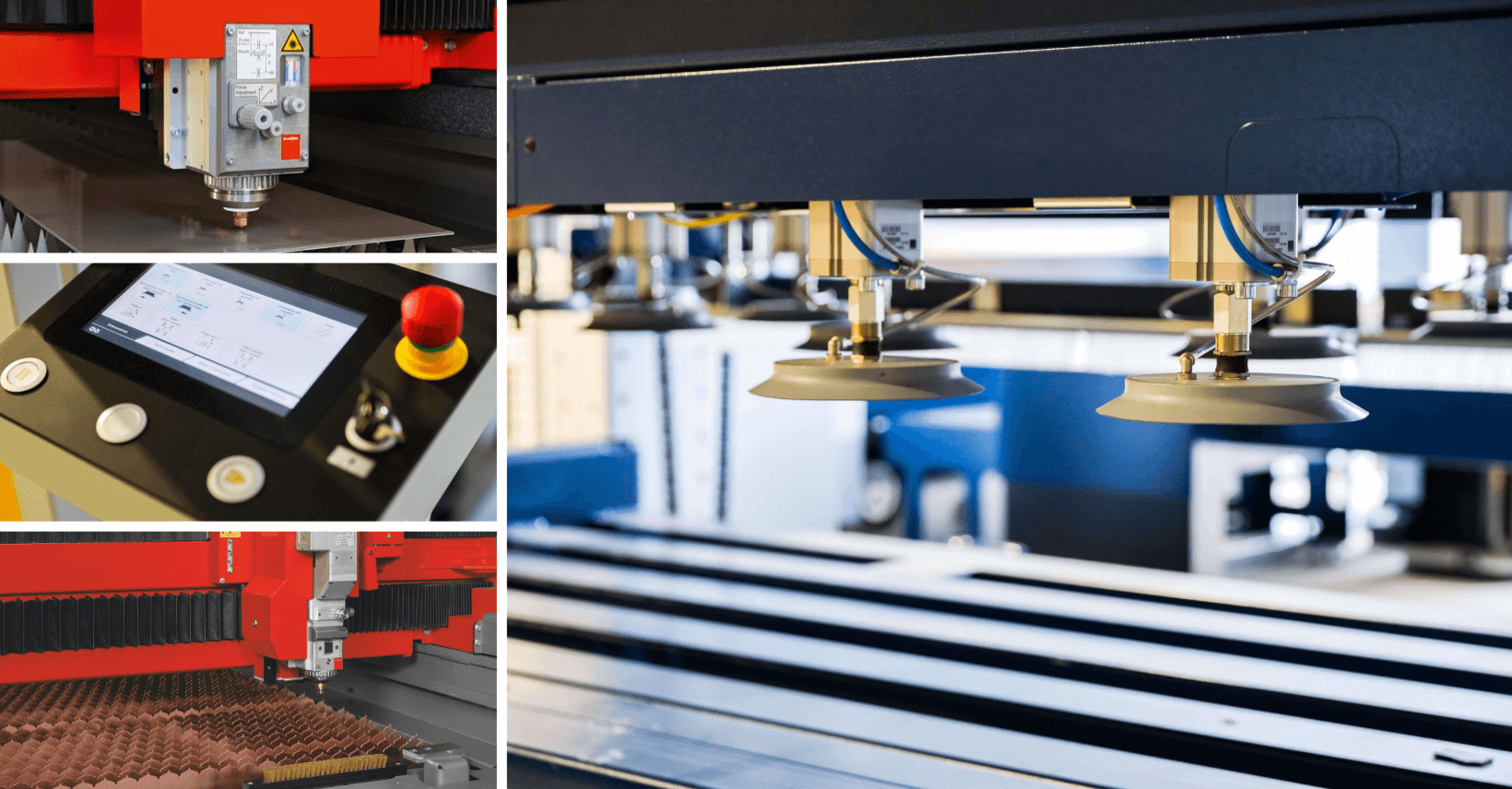

Our beginnings were humble, with just one CO2 Bystronic laser cutter, a press brake, and a passionate team of eight dedicated employees.

At the outset, we used the laser and press brake to enhance the manufacture and fabrication of a variety of products, including hose reels, fuel and water tanks, van racking and shelving, as well as sectional frames for our sister company, HydraMaster.

As we expanded, we diversified by offering subcontracted laser cutting services, to both local and national businesses, engineers and individuals.

This growth allowed us to establish a strong reputation in the industry, as we consistently delivered quality and precision in our work.

Our commitment to customer satisfaction has always been at the forefront of our operations, driving us to adapt and evolve with the needs of our clients.

In 2012, we took a major step forward in enhancing our operational capabilities by upgrading our laser cutting technology. Transitioning from a single CO2 laser to a state-of-the-art 4 kW fibre optic laser cutter significantly improved our efficiency and allowed us to better respond to the increasing demand for our services. This upgrade not only streamlined our processes but also positioned us to take on more complex projects, further solidifying our place in the market.

Keeping up with the Demand For Sub Contracted Laser Cutting, Folding and Fabrication.

Over the subsequent years, we made significant strides in our metal fabrication capabilities, transitioning from a 4 kW to a 6 kW laser and adding a 10 kW Bystronic fibre laser and our most recent addition a 12 kW Trumpf to our line up. By equipping all our laser machines with automatic sheet loaders as standard, further boosting productivity and ensuring efficient operations.

Laser cutting metal requires a steady flow of nitrogen gas to form a protective shield and avoid combustion. To enhance our operations, we decided to invest in a Atlas Copco nitrogen generator. Previously, we depended on bulk deliveries from a supplier, with tankers regularly coming to replenish our nitrogen storage silo. By switching to an on-site nitrogen generator, we have significantly lowered our carbon emissions, as we no longer need to rely on external deliveries.

Expanding Our Services

From our modest beginnings, we have been steadily increasing our machinery to enhance our sheet metal cutting services, including new press brakes, a vibro tumbler (rumbling machine), linishers, and a vapour blaster.

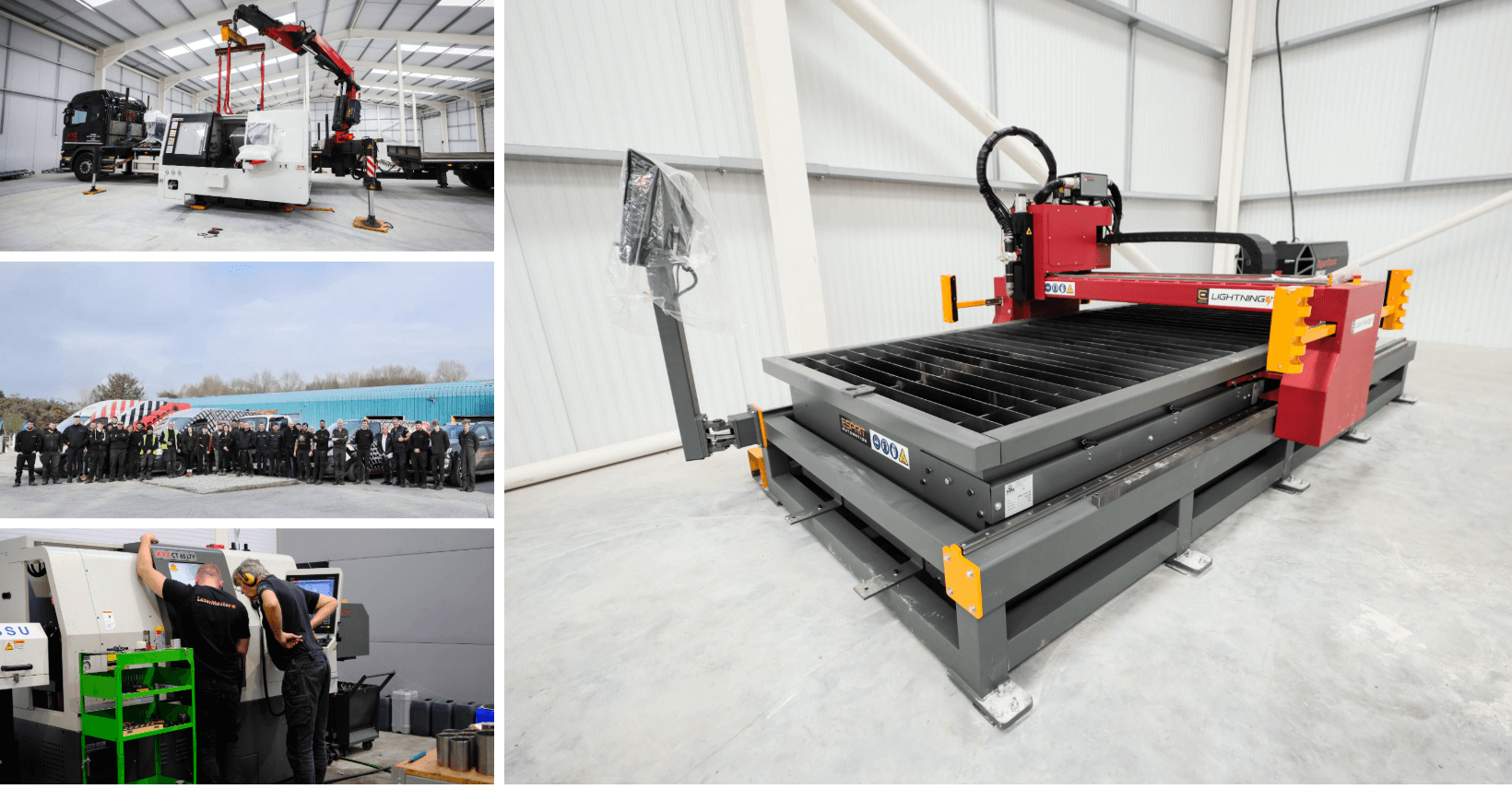

In 2022, LaserMaster experienced significant expansion by strengthening our CNC machining department through the acquisition of Chapel Engineering. This not only brought in new team members with a wealth of knowledge and skills, but also introduced cutting-edge machinery to our arsenal.

Due to the escalating demand, we outgrew our current warehouse. Consequently, we made the decision to construct a new 22,000 sq. ft factory on site.

This new space accommodates an advanced Esprit HD plasma cutting machine, CNC machine shop fully equipped with the latest CNC mills, lathes, and turning centres, as well as a spacious welding and fabrication area for the production of large industrial assemblies.

With a larger team and advanced equipment at our disposal, we are fully equipped to meet the evolving needs of our clients. This expansion has opened up new avenues for us to excel in precision engineering. Our newly constructed factory not only offers more space for our operations but also showcases our dedication to innovation and progress.

In 2024, we established an on-site powder coating facility, allowing us to deliver fully finished orders directly from our premises. This development enhances our operational efficiency and ensures that our customers receive their products in a timely manner, all while maintaining our dedication to high-quality standards.

Committed to Customer Satisfaction

Today, we are a dedicated team of 48 members, including talented laser, plasma, press brake, and CNC operators, powder coaters, along with skilled CAD technicians, coded welder fabricators, and a committed dispatch team.

Our commitment to excellence is reflected in our ISO 9001 & 14001 accreditation.

Our steadfast dedication to customer satisfaction has propelled us to become a prominent nationwide provider of subcontracted metal laser cutting, plasma cutting, metal folding and bending, welding, fabrication, power coating and CNC machining services.

So, whether you have a small custom order, a prototype, or a large manufacturing production run, we guarantee that every customer receives the same level of care and attention to detail.

Committed to delivering outstanding customer service and retaining the personal touch, LaserMaster’s family business values will always remained at our core.

Careers at LaserMaster

LaserMaster is an ever expanding manufacturing company that continually seeks skilled and dedicated individuals to become part of our expanding team. If you are interested in pursuing a career with LaserMaster, kindly submit your CV to careers@lasermaster.co.uk.

We hold accreditations in ISO 9001, ISO 14001, CHAS, and SMAS, reflecting our commitment to health and safety standards. Additionally, we are a living wage employer.

Current Vacancies