When it comes to manufacturing and prototyping, CNC machining plays a crucial role in ensuring precision and efficiency. From aerospace components to medical devices, CNC machining offers a wide range of benefits that make it a preferred choice for many industries.

Precision One of the primary advantages of CNC machining is its ability to produce parts with unparalleled precision. The computer-controlled system ensures that each cut and movement is exact, resulting in consistent and accurate parts every time. This level of precision is essential for industries where tight tolerances are required, such as aerospace and medical.

Efficiency: CNC machining is known for its efficiency in producing parts at a rapid pace. Unlike manual machining, CNC machines can operate continuously without the need for breaks, resulting in higher productivity and shorter lead times. This efficiency translates to cost savings for manufacturers and allows for faster turnaround times for projects.

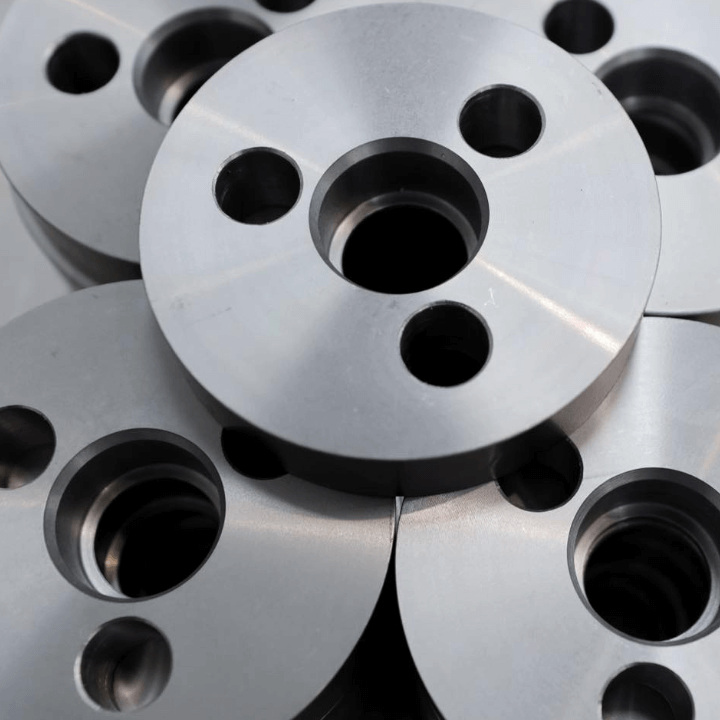

Versatility: Another key benefit of CNC machining is its versatility in producing a wide range of parts and components. From simple designs to complex geometries, CNC machines can handle various shapes and sizes with ease. This flexibility makes CNC machining ideal for prototyping, customization, and small-batch production runs.

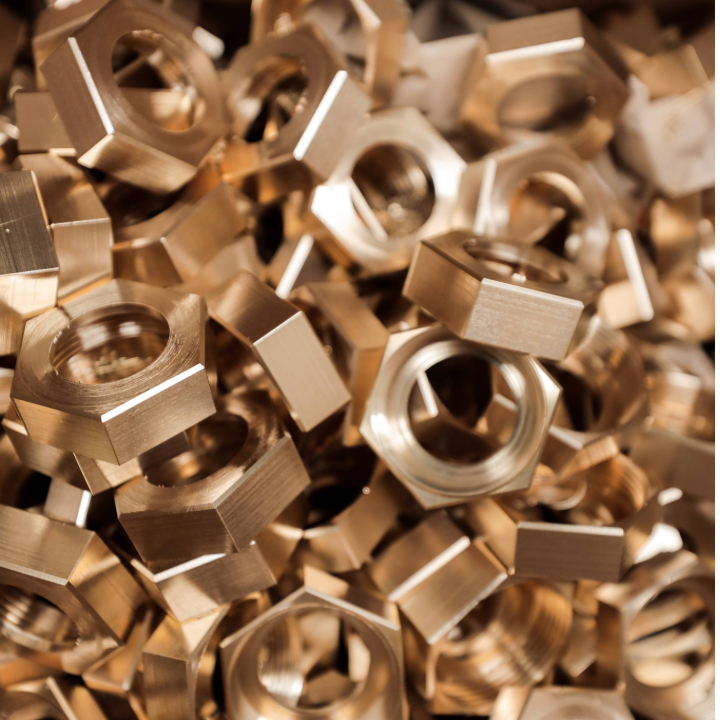

Consistency: is crucial in manufacturing, and CNC machining excels in delivering uniformity across multiple parts. With the ability to program and replicate designs accurately, CNC machines ensure that each part meets the same specifications and quality standards. This consistency reduces waste and minimizes errors in production.

Automation: is a significant advantage of CNC machining, as it eliminates the need for manual labour and reduces the risk of human error. Once the program is set up, CNC machines can operate independently, freeing up operators to focus on other tasks. This automation results in higher efficiency, lower labour costs, and improved safety in the workplace.