Our Customer Stories

Laser Cutting and Folding For Boyesen Design

Artist and Designer Sebastien Boyesen - Based in West Wales, Sebastien works on projects throughout the UK.

Sebastien Boyesen began his career as an artist and designer after being awarded his first public commission in 1984. For more than three decades, Sebastien has focused on creating both sculptural and two-dimensional artworks designed to engage and interact with their surroundings, rather than existing as standalone pieces.

Collaborating with councils and corporate clients Sebastien is passionate about integrating art within new developments, urban projects, and regeneration schemes. Believing it is vital to celebrate the beauty of art and design in built environments and strives to create uplifting and inspiring spaces where people live, work and play. His works include The Guardian at Abertillery, South Wales.

Laser Cut and Folded Aluminium Panels

Tunsgate Quarter – Guildford Surrey

LaserMaster have had the pleasure of working with Sebastien on several projects to date. The first was in 2017 when he contacted us to see if we would be interested in quoting for the laser cutting and folding the 3 mm aluminium panels for the Tunsgate Quarter, in Guildford, Surrey.

Sebastien admitted we were not the only laser cutting company he had contacted regarding this project, but later confessed we were the only one to accept the challenge.

This was the first time we tackled a project with this amount of detailed laser cutting. The task comprised of 140 individually distinct decorative panels in assorted sizes and shapes. Laser cut from 3 mm thick 5083 aluminium and each featured four 90 degree folds to enhancing durability and enabling the installation at Tunsgate.

Starting with prototype panels, to check the bend development was correct and that the distance from the detail to the fold was sufficient enough so that the pattern did not deform during folding.

Once all the testing was done Sebastien supplied the CAD files in their 2D flat view, perfect for importing directly into the laser cutting software, with additional PDF’s showing all panels once folded.

One key aspect we needed to consider was minimising the risk of collisions between the laser cutting head and the panel by optimising the laser head's path. This involved reducing unnecessary travel over already cut detail that could be protruding into the laser heads path. By preventing the laser head from colliding with any obstacles reduced the risk of any movement of the sheet whilst cutting and in addition prevented costly damage to the laser cutting head. The intensity of the laser cutting process can cause sheet metal to bow, so the laser operators have to be extra vigilant.

Checking the path was correct on all 140 panels required some patience and time, but the end result was worth the effort to guarantee everything ran smoothly. The complete order used forty 2500 mm x 1250 mm sheets of 3 mm aluminium, by minimising the risk of collision meant only 4 panels needed to be re cut due to slight movement.

After being laser cut and ‘skinned’ from the sheets, the flat aluminium panels were then run through the linishing machine to remove any burrs, soften the edges and apply a 'key' for painting. Then onto the folding department where they all receive precise 90 degree folds on all four sides of each panel. Finally, the panels were ready for powder coating. Once finished we delivered direct to the Tunsgate in Guildford where Sebastien and his team took care of the installation.

Decorative Laser Cut Stainless Panels

The Wichelstowe Footbridge - Wilts and Berks Canal

Commissioned by Swindon Borough Council to connect new retail amenities and housing with the Waitrose supermarket that is located on the opposite side of the canal. The Wichelstowe Foot Bridge is approximately 60 m in length, with a stainless steel and resin design.

During the initial stages, test cuts were carried out on 3mm mild steel which was suitable material for checking the design. However, the final laser cut panels were fabricated from 3mm 316 stainless steel with a 2b finish. This project was slightly easier than Tunsgate. We again optimised the cutting path on each of the decorative panels, but there were repeats of the same design, making it less time consuming at the initial nesting stage.

Once the laser cutting was completed the panels underwent deburring and edge softening using a linishing machine. Ensuring they had a more uniform finish and no sharp edges.

Sebastien organised for them to be delivered direct to a dedicated stainless steel finishing company for chemical treatment to ensure the longevity of the stainless material. This was done before proceeding with the final installation of the panels into the main bridge structure.

Laser Cutting Free Issue Cor-Ten Weathering Steel

The Centurion-The Gwent Levels Sculpture trail

Standing at a height of about 2.4m, this sculpture is crafted from Corten steel, known for its weathering properties that create a protective layer. Weighing around 300kg, the figure is composed of metal layers with spaces in between, allowing light to pass through and giving it a spectral effect. To bring this artwork to fruition, a human model wearing replica Roman Centurion attire from the 2nd century was digitally scanned. The resulting 3D figure was then transformed into a virtual sculpture, and 3000 CorTen steel parts were laser-cut and welded together to form the final masterpiece.

With this project we quoted solely for the laser cutting and etching of the profiles from the free issued CorTen weathering steel. Sebastien arranged for the delivery of CorTen sheets directly from his supplier to us. Once the shapes were laser cut, we sent the whole sheets back to his workshop with the parts still ‘tagged’ within the sheets.

Upon opening Sebastien's CAD files, we were unsure of what they would eventually become. Each profile was marked with a unique identification number to be etched, but the profiles themselves seemed like a jumble of random shapes. Neither the CAD file names, or identification numbers gave anything away.

When Sebastien sent over some images with all 3000 pieces welded together and his commission installed in place, we were astounded by the final result.

Laser Cutting Free Issue Cor-Ten and Stainless Steel

The Tree of Life Sculpture - Wichelstowe Swindon

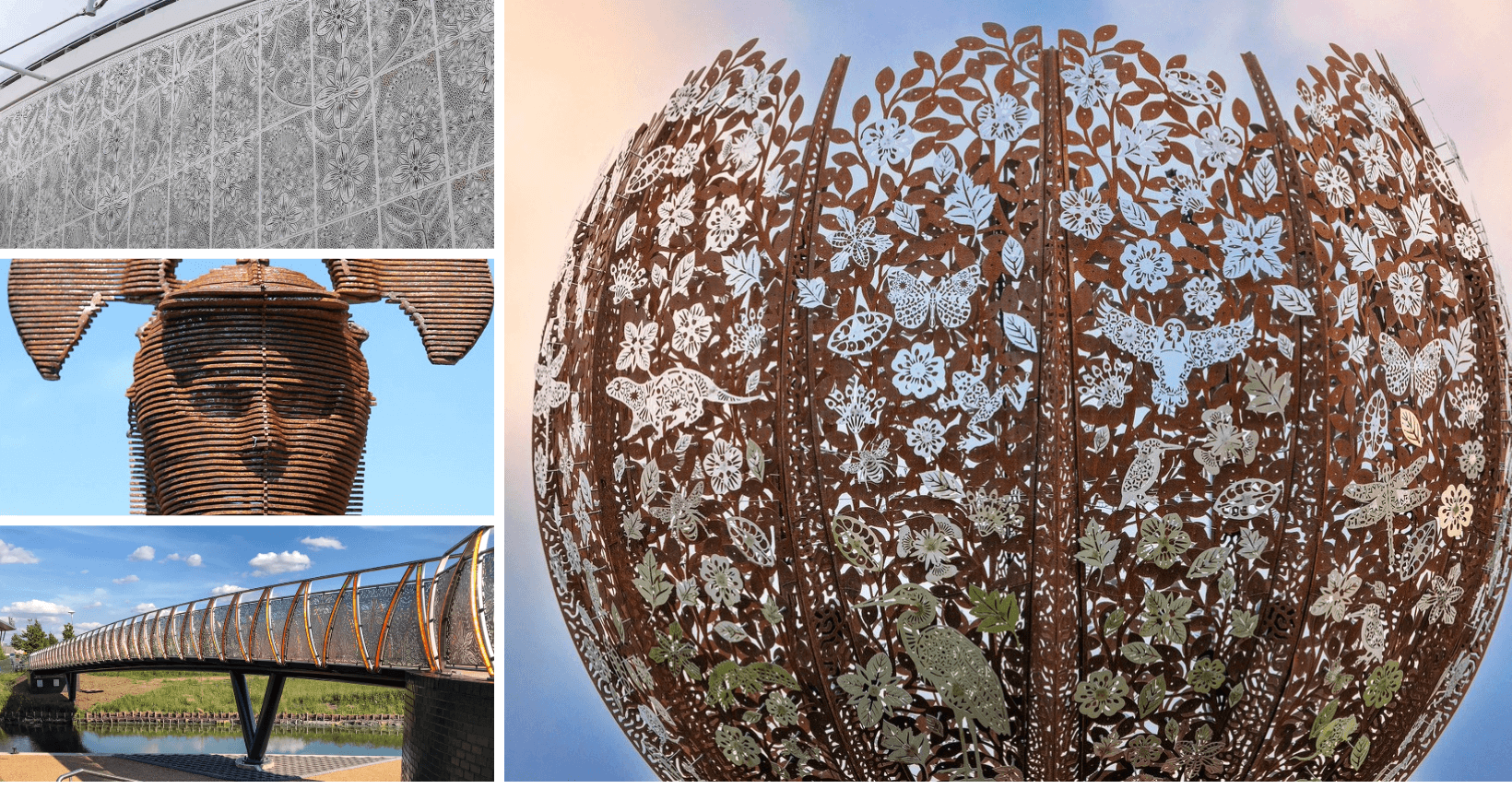

The Tree of Life sculpture, created by Sebastien Boyesen, stands at 5.6m tall and 4.4m wide at the new roundabout on Mill Lane in Wichelstowe. It serves as a striking entrance into the area, featuring stainless steel flora and fauna on a steel base.

The intricate design includes laser-cut corten panels forming a globe shape, connected with rods of varying lengths to create this three dimensional sculpture. Decorated with stainless steel profiles featuring a vast array of wildlife native to Wiltshire and commonly found in Wichelstowe, including water voles, bees, dragonflies, forget-me-nots, hawthorn, dog roses, and the beloved heron.

At night, the sculpture illuminates from within, creating a captivating glow. The trunk and main structure were installed, with Sebastien and his team working on-site to assemble the branches.

This order was a combination of free issue laser cutting of 3 mm and 5 mm CorTen weathering steel and 316 grade DP1 1.5mm thick stainless steel (brushed finish) which we supplied. Sebastien supplied the CAD files for the cutting. Once again, we spent time optimising the cutting path of the lasers to minimise any problems during the process, special care was taken when nesting the leaf panel designs onto the CorTen free issued sheet, because we had price just to cut only so limiting any issues at this stage was a priority.

Sebastien provided us with a list of the quantities needed for each ready sized stainless profile, which included a diverse range of intricately patterned leaves, flowers, insects, animals, amphibians, and birds. He also gave us the flexibility to resize any of the designs to perfectly fit any remaining spaces on the sheet, ensuring optimal sheet usage. With no further finishing required on our part the profiles were then shipped direct to Sebastien’s workshop along with the CorTen leaf panels and globe supports.

Manufacturing for Thousands of Businesses and Individuals

Google Reviews

Regardless of the scale of the order, we pay special attention to each client, so they come back to us