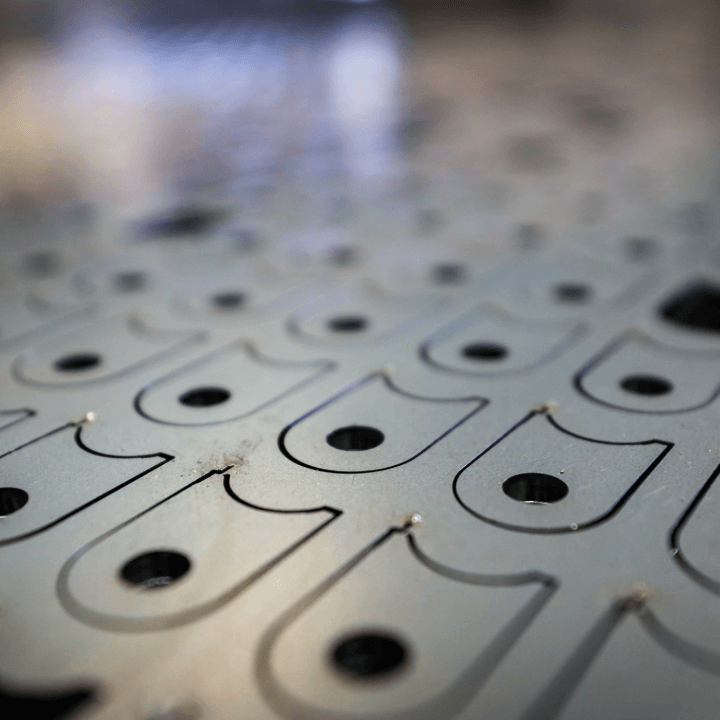

Deburring metal parts helps ensure safety, as burrs left on metal parts can pose a sharp and hazardous threat to workers and end users. By removing burrs, metal parts become safe to handle and use. Deburring metal parts is not only essential for safety but also for functionality.

Burrs left on moving metal parts can hinder their performance, causing gears to jam or wear out quickly. Removing burrs ensures that metal parts function properly, enhancing their performance and longevity.

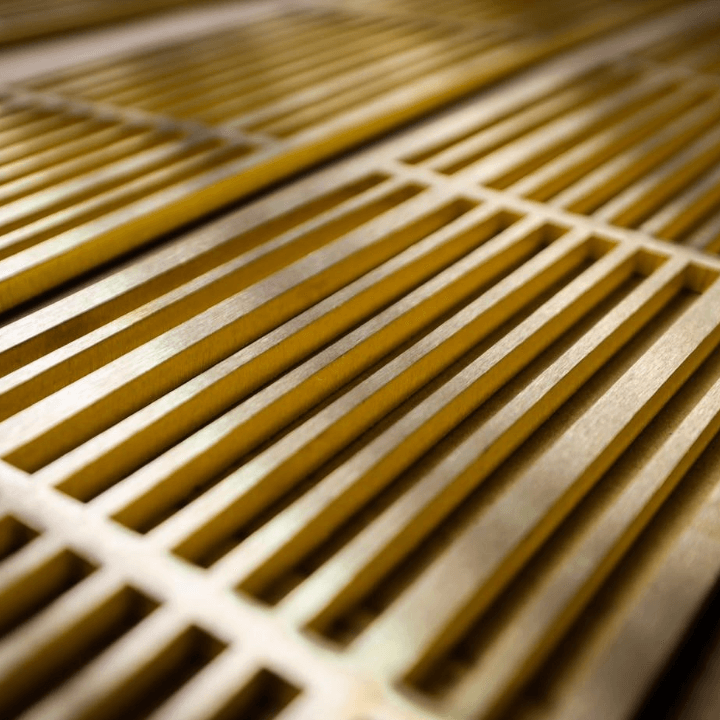

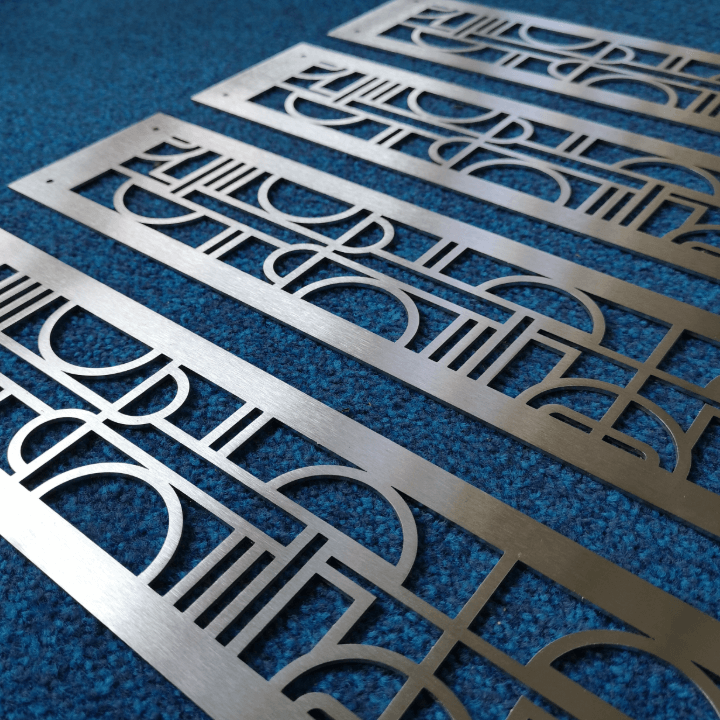

In addition to safety and functionality, deburring metal parts can also enhance their aesthetic appeal. By creating a more uniform aesthetic finish, deburring can give metal items a professional and high-quality appearance.

Removing burrs on metal parts can help prevent corrosion. Burrs left behind can retain moisture and contaminants that promote corrosion and rust over time. Deburring eliminates crevices where corrosion agents can gather, thereby increasing the lifespan of metal components.

Deburring metal parts can improve the efficiency of the production process. Metal burrs can cause delays and quality control issues, slowing down manufacturing and raising costs. Deburring metal parts can help streamline the production process, making it more efficient and cost-effective.